How can automation enhance quality control in chemical processes? Automation can streamline monitoring and testing procedures, ensuring consistency and reducing human error.

How can automation enhance quality control in chemical processes? This question is vital for industries aiming to optimize their operations. In this post, we will explore the transformative role of automation in enhancing quality control, particularly in the chemical sector. Prepare to discover innovative ways that automation not only ensures compliance with industry standards but also boosts efficiency and reduces costs. By the end, you’ll understand how integrating automated systems can lead to superior product quality and more reliable processes.

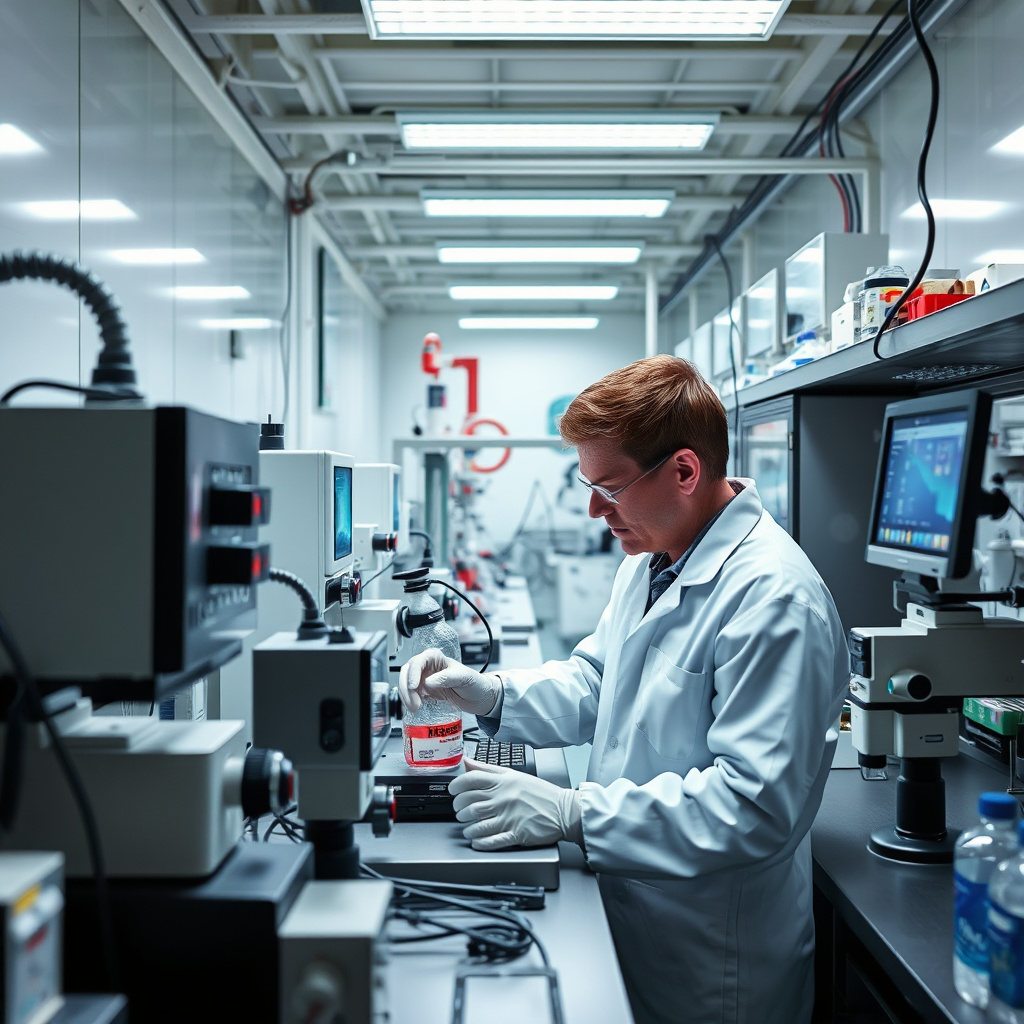

In today’s fast-paced chemical manufacturing landscape, the quest for efficiency and quality has never been more critical. As industries strive to meet rigorous safety standards and customer expectations, the question arises: how can automation enhance quality control in chemical processes? This article delves into the transformative power of automation, offering insights that can elevate your manufacturing practices.

Understanding the Basics of Quality Control in Chemical Manufacturing

Quality control (QC) is a systematic process aimed at ensuring that chemical products meet specified standards. It encompasses various activities designed to monitor and maintain quality throughout the production cycle. Key elements of QC include:

- Quality Assurance: A proactive approach that ensures processes are designed to meet quality standards.

- Testing and Inspection: Regular assessments to identify deviations from quality benchmarks.

- Feedback Loops: Mechanisms for continual improvement based on quality data.

Effective quality control directly impacts production efficiency, reducing waste and enhancing product reliability. By understanding these fundamentals, organizations can better appreciate the role of automation in streamlining QC processes.

The Advantages of Implementing Automation in Quality Control

Integrating automation into quality control processes presents numerous advantages:

- Enhanced Accuracy: Automated systems provide precise measurements and consistent monitoring, minimizing variations that may arise from human error.

- Real-Time Monitoring: Automation allows for continuous oversight of production parameters, enabling immediate corrective actions when necessary.

- Improved Product Consistency: Automation standardizes processes, which is crucial for maintaining uniform quality across batches.

As experts in the chemical sector, we at DIPLOMATA COMERCIAL have witnessed firsthand the profound impact of these advantages on overall manufacturing outcomes.

Key Criteria for Evaluating Automation Solutions

When considering automation for quality control, it is essential to evaluate potential solutions based on the following criteria:

- Compatibility: Ensure that the automated system integrates seamlessly with existing operational frameworks.

- Scalability: Choose solutions that can grow with your business needs, accommodating future expansions.

- Ease of Use: Select user-friendly interfaces to facilitate staff training and reduce transition times.

- Comprehensive Data Analytics: Opt for systems that provide detailed analytics, helping to inform decision-making and optimize processes.

Step-by-Step Guide to Implementing Automation in Quality Control

Implementing automation in quality control can seem daunting, but following a structured approach can simplify the process:

- Initial Planning: Define your goals and objectives for automation.

- System Selection: Research and choose the right automation tools that fit your criteria.

- Installation: Collaborate with technical teams to ensure proper setup and integration.

- Staff Training: Provide comprehensive training to employees to maximize the benefits of the new system.

Advanced Techniques and Best Practices for Quality Automation

To maximize the effectiveness of automated quality control systems, consider employing advanced techniques:

- Data Integration: Utilize systems that allow integration of data from various sources for a holistic view of quality metrics.

- Continuous Improvement Methodologies: Implement practices like Six Sigma or Lean Manufacturing to enhance quality processes continually.

- Leveraging AI: Use artificial intelligence for predictive analytics, identifying potential quality issues before they arise.

Common Pitfalls in Automated Quality Control and How to Avoid Them

Despite the benefits, automation in quality control can present challenges. Here are common pitfalls and strategies to avoid them:

- Inadequate Training: Ensure thorough training to prevent operational errors.

- Poor System Integration: Collaborate with IT specialists to facilitate smooth integration with existing systems.

- Neglecting to Update Processes: Regularly review and upgrade automation tools to ensure they remain effective and relevant.

By being aware of these potential issues, organizations can navigate the transition to automated quality control more effectively.

Conclusion

Incorporating automation into quality control processes is not just a trend; it is a necessity for chemical manufacturers aiming for excellence. By understanding the fundamentals, evaluating solutions carefully, and implementing best practices, companies can significantly enhance their quality assurance efforts. As the industry continues to evolve, embracing automation will be key to staying competitive and ensuring product integrity.

Expertise in Chemical Quality Control

This content reflects profound expertise in the chemical industry. With 20 years of experience, our specialization as a manufacturer of glycerin, using our own facilities, and being a renowned supplier positions us as a trusted source on how automation can enhance quality control in chemical processes.

Our Location: Av. Ipanema N° 165 – Empresarial 18 do Forte, Barueri – SP. CEP: 06472-002

Frequently Asked Questions

How does automation improve quality control in chemical processes?

Automation enhances quality control by reducing human error, ensuring consistent monitoring of critical parameters, and enabling real-time data analysis. Automated systems can quickly detect deviations from established standards, allowing for immediate corrective actions, which ultimately leads to improved product quality and safety.

What technologies are used in automating quality control in chemical processes?

Common technologies include sensors for real-time monitoring, automated data collection systems, and advanced analytical tools like machine learning algorithms. These technologies help in assessing product quality, predicting potential issues, and optimizing processes to maintain high standards.

Can automation reduce costs in chemical quality control?

Yes, automation can significantly reduce costs by increasing efficiency, minimizing waste, and decreasing the need for manual inspections. By streamlining processes and improving accuracy, automated quality control can lead to lower operational costs and enhanced profitability over time.

What are the challenges of implementing automation in quality control?

Challenges include the high initial investment in technology, the need for skilled personnel to operate and maintain automated systems, and potential resistance to change within the organization. Additionally, integrating automation with existing processes can be complex and requires careful planning.

How does automation impact compliance in chemical processes?

Automation helps ensure compliance with industry regulations by providing consistent documentation and traceability. Automated systems can generate reports and maintain records automatically, reducing the risk of non-compliance and facilitating easier audits and inspections.